Supply Chain Management Review, (SCMR), is a U.S. business magazine that discusses supply chain trends. This magazine provides a wide perspective on the supply chain including the roles of manufacturers and suppliers. This magazine also features an in-depth analysis of the most recent technologies and trends. Visit SCMR's website for more information. Download the latest issue. If you're looking for industry insight, subscribe to the magazine today.

Autonomous mobile robots

Autonomous Mobile Robots (AMRs) are a growing trend in warehouse automation, and their introduction is likely to make a big impact on many aspects of the supply chain. These robots have the ability to create their own routes and operate in dynamic environments. They are also less likely to need manual picking which results in better productivity. By removing the need for manual walking, AMRs can significantly reduce labor costs and boost productivity.

Blockchain

Supply chain management has become a critical part of a company’s success in an era of global competition. Companies need to be responsive, flexible, and agile in order to stay competitive. By driving continuous innovation, they can be different. To realize these goals, it's important to improve the efficiency and effectiveness of the entire supply chain. Blockchain technology is one method to accomplish this. Blockchain is similar to a Google Document. Users can share the blockchain with others, allowing them to make changes immediately.

Real-time data

Supply chain management has changed rapidly. Real-time data is a great tool to assist supply chain managers in managing their businesses better. Companies can monitor and control their inventory levels using item-level data, which allows them to avoid overages. Additionally, retailers can use real-time data to predict and respond in time to shipping delays. This improves customer satisfaction. Real-time data can be used to manage inventory and to make decisions about future operations. This is a great way for businesses to increase productivity.

S&OP

For the latest trends in supply chain management, read Supply Chain Management Review. This American business magazine covers a wide range of topics including new developments and global trends. It provides information on tools and techniques for supply chain management. For a business to succeed, it is essential that they keep abreast of the latest trends in supply chains management. In addition to reporting on the latest trends in supply chain management, the magazine offers advice on how to improve business operations.

Adapting for change

Owners of businesses need to learn how to adapt to changing supply chain management. Supply chains around the globe were badly disrupted during the recent pandemic. All efforts to contain it led to long shutdowns. Supply chains are now more susceptible to sudden shocks like the 9/11 terrorist attacks, the dockworker strikes and the SARS epidemic. Despite the complexity in supply chains most companies aren't equipped to deal with an emergency. Companies forget contingency plans and leave their supply chains vulnerable to disruption.

Supply Chain Management Goals

An organizational supply chain management review can help improve their ability for change. Supply chains are crossfunctional processes that move raw materials in and out a business. These processes cover inventory management, transportation and returns. The goal is reduce disruption and increase flexibility. It is also important to understand the effects of these changes on a company's profits. You can learn how a supply management review can be beneficial to your business by reading on.

FAQ

What is a basic management tool used in decision-making?

The decision matrix is a powerful tool that managers can use to help them make decisions. It allows them to think through all possible options.

A decision matrix is a way of representing alternatives as rows and columns. It is easy to see how each option affects the other options.

In this example, we have four possible alternatives represented by the boxes on the left side of the matrix. Each box represents an option. The top row displays the current situation, and the bottom row shows what might happen if nothing is done.

The effect of Option 1 can be seen in the middle column. In this example, it would lead to an increase in sales of between $2 million and $3 million.

These are the results of selecting Options 2 or 3. These are positive changes - they increase sales by $1 million and $500 thousand respectively. However, these also involve negative consequences. Option 2, for example, increases the cost by $100 000 while Option 3 decreases profits by $200 000.

Finally, the last column shows the results of choosing Option 4. This will result in sales falling by $1,000,000

The best part about using a decision matrix to guide you is that you don’t need to keep track of which numbers go where. The best thing about a decision matrix is that you can simply look at the cells, and immediately know whether one option is better or not.

The matrix has already done all of the work. It's simply a matter of comparing the numbers in the relevant cells.

Here's a sample of how you might use decision matrixes in your business.

You want to decide whether or not to invest more money into advertising. By doing so, you can increase your revenue by $5 000 per month. You'll also have additional expenses up to $10,000.

The net result of advertising investment can be calculated by looking at the cell below that reads "Advertising." It is 15 thousand. Advertising is more valuable than its costs.

What is the difference in leadership and management?

Leadership is all about influencing others. Management is about controlling others.

Leaders inspire followers, while managers direct workers.

Leaders inspire people to achieve success. Managers keep their workers focused.

A leader develops people; a manager manages people.

What does Six Sigma mean?

Six Sigma uses statistics to measure problems, find root causes, fix them, and learn from past mistakes.

First, identify the problem.

Next, data are collected and analyzed in order to identify patterns and trends.

The problem can then be fixed by taking corrective measures.

Final analysis of data is done to determine if the problem has been solved.

This cycle continues until the problem is solved.

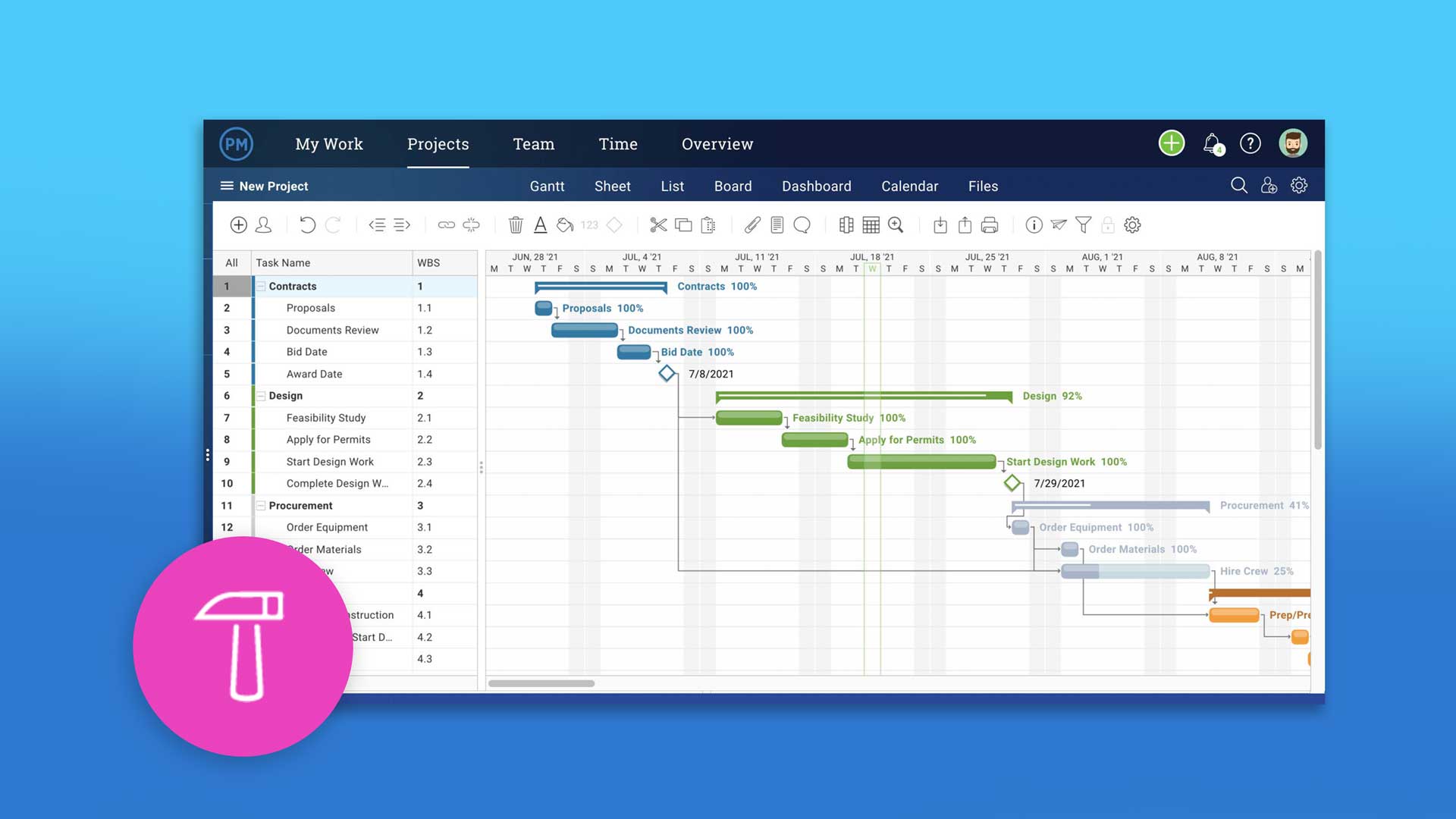

What does the term "project management” mean?

Management is the act of managing activities in order to complete a project.

We include defining the scope of the project, identifying the requirements, preparing the budget, organizing the project team, scheduling the work, monitoring progress, evaluating results, and closing down the project.

What is Kaizen and how can it help you?

Kaizen refers to a Japanese term that stands for "continuous improvements." It is a philosophy which encourages employees in continuously improving their work environment.

Kaizen is built on the belief that everyone should be able do their jobs well.

What are the top management skills?

Any business owner needs to be able to manage people, finances, resources and time. These skills include the ability manage people, finances and resources as well as other factors.

Managerial skills are required when setting goals and objectives and planning strategies, leading employees, motivating them, solving problems, creating policies, procedures, or managing change.

As you can see there is no end to the number of managerial tasks.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

External Links

How To

How do you apply the Kaizen method to your life?

Kaizen means continuous improvement. Kaizen is a Japanese concept that encourages constant improvement by small incremental changes. It's a team effort to continuously improve processes.

Kaizen is one method that Lean Manufacturing uses to its greatest advantage. Kaizen is a concept where employees in charge of the production line are required to spot problems during the manufacturing process before they become major issues. This will increase the quality and decrease the cost of the products.

Kaizen is the idea that every worker should be aware of what is going on around them. If something is wrong, it should be corrected immediately so that no problem occurs. So, if someone notices a problem while working, he/she should report it to his/her manager.

Kaizen is based on a few principles. We always start from the end product and move toward the beginning. We can improve the factory by first fixing the machines that make it. First, we fix machines that produce components. Next, we fix machines that produce raw material. Finally, we repair the workers who are directly involved with these machines.

This method is known as kaizen because it focuses upon improving every aspect of the process step by step. Once we have finished fixing the factory, we return to the beginning and work until perfection.

It is important to understand how to measure the effectiveness and implementation of kaizen in your company. There are several ways to determine whether kaizen is working well. Another method is to see how many defects are found on the products. Another way is determining how much productivity increased after implementing kaizen.

Another way to know whether kaizen is working is to ask yourself why did you decide to implement kaizen. Was it just because it was the law or because you wanted to save money? It was a way to save money or help you succeed.

If you answered yes to any one of these questions, congratulations! Now you're ready for kaizen.